CMU partners with ANSYS to drive the next industrial revolution in making physical products

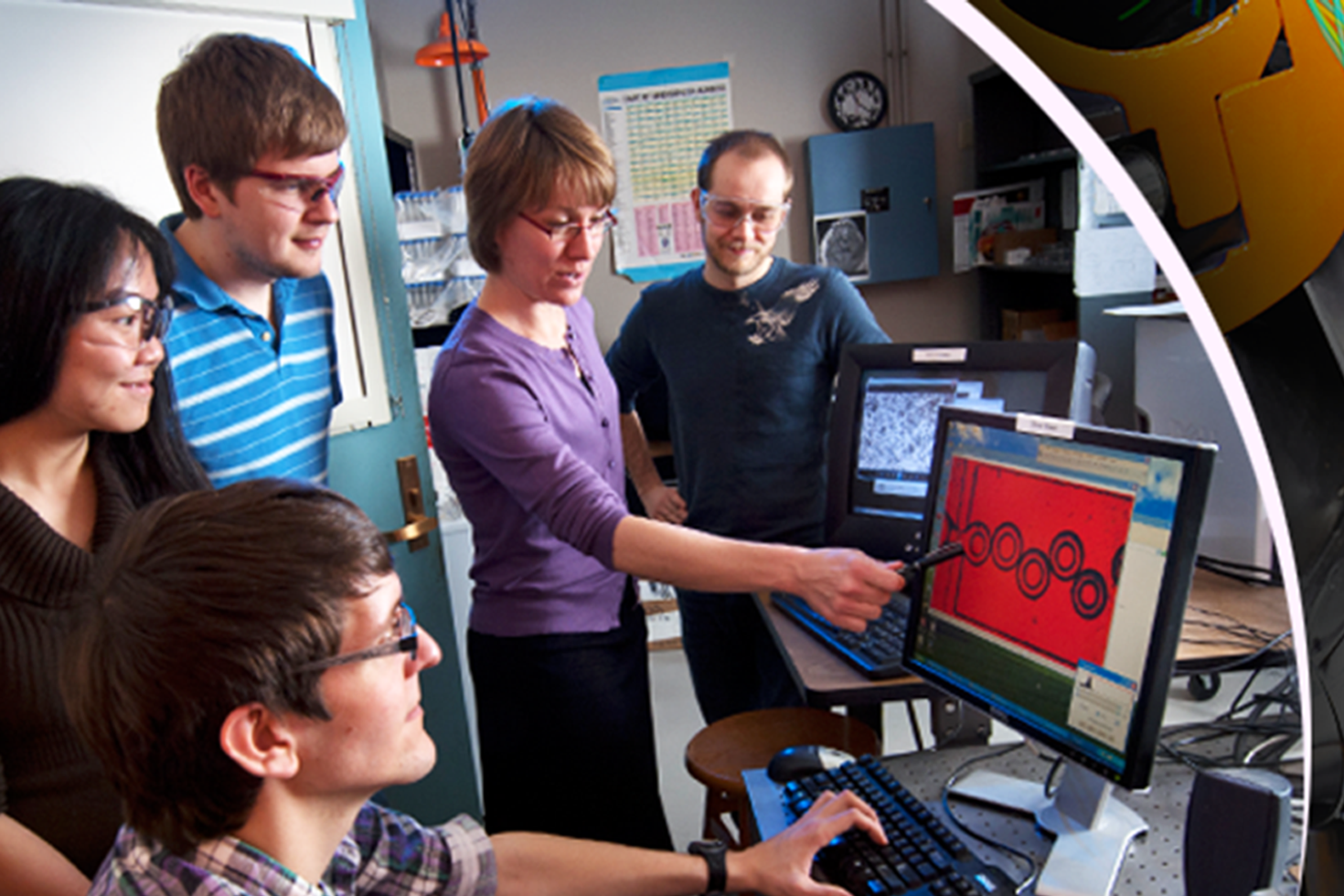

In any ecosystem, there is a network of interactions among its occupants linked by an energy flow that is supported by the various component resources in that ecosystem. Carnegie Mellon University’s maker ecosystem is just that. Faculty and students—experts and experts-to-be—work,

The maker ecosystem spans many activities in the College of Engineering, particularly those housed in the newly-completed Scott Hall and the redesigned Hamerschlag MakerWing. A new 30,000 square foot facility, the ANSYS Building, will expand the making capabilities of the College with a simulation and collaboration lab and a large open bay facility for undergraduate students to build full-scale projects.

“Thanks to the generosity of ANSYS, a new cornerstone building will provide a maker facility where students will have access to simulation tools and cutting-edge technologies for the hands-on work that is a hallmark of our CMU education,” said James Garrett, dean of the College of Engineering.

Making comes naturally to the College, where hands-on problem solving spans the academic programs as well as the recreational ones: Spring Carnival’s famous buggy races, the Department of Electrical and Computer Engineering’s Build18 free-style tinkering competition, and the Formula SAE Electric Racing Team, for example.

Because the new open bay facility will be next door to the fabrication and machining facilities of Hamerschlag’s MakerWing, students will be able to make their components and then assemble them into larger systems.

Additional features of the new ANSYS Building will include collaboration areas, conference rooms, training and lecture space, and office space. Another element of ANSYS’ gift is the funding of the ANSYS Career Development Chair in Engineering. The endowed Early Career Professorship will be awarded to a faculty member who is conducting education and research in areas related to engineering simulation software.

A new partnership, a new engineering workforce

Manufacturing and product innovation

“The traditional design and manufacturing methods have clearly become sub-optimal,” said James Cashman, president

If a prototype didn’t work, the engineer literally had to go back to the drawing board.

Simulation software, however, is part of the manufacturing revolution that will make the old methods obsolete. How? Physics-based computational tools can digitally test—and discard—millions of permutations of designs, materials,

This all happens before an engineer needs to build a single physical prototype—and when they do, it’s for final validation of the design, not to test it for flaws. Instead of being limited by restrictions, engineers will have unparalleled opportunities for exploration at the beginning of the process.

“Engineers can explore ideas as fast as they can imagine them, without being bogged down by the traditional process,” said Garrett. “This will eliminate barriers that keep new ideas from turning into actual products.” Another benefit: the whole process becomes much quicker, cheaper, and more environmentally sustainable.

But this will require a major shift in education, which is where ANSYS and Carnegie Mellon’s partnership steps in. The two leaders want to leverage

And they want to make this knowledge and use available and relevant to all

The maker ecosystem and its MakerWing

Another important component of the College’s maker ecosystem is the development of the MakerWing in Hamerschlag Hall. There, hands-on learning experiences will integrate with high-impact, solutions-based research in 40,000 square feet of transformed space on two floors.

Students will immerse themselves in the College’s learning-by-doing culture in the design workshops, the rapid prototyping lab, the machine and professional shops, and the electronic fabrication facilities. Research laboratories and open, clustered workspaces will provide faculty and students with opportunities to share ideas through spontaneous interactions.

The MakerWing, along with the new ANSYS Building, will facilitate new manufacturing technologies, creative processes, and innovative solutions that will stretch beyond our collective imaginations into the future.

Learn more about our partnership with ANSYS: