|

|

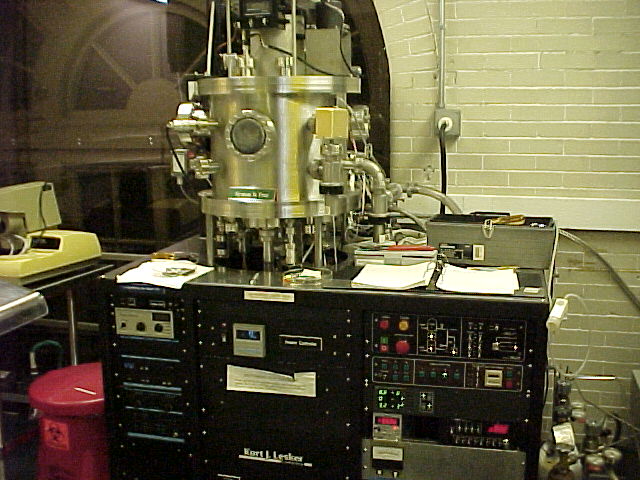

KJLesker Sputtering System

The Lesker sputtering system is a large vacuum chamber where an inert

(or reactive) gas atmosphere is introduced along with the generation of a

plasma across a target material and substrate. Sputtering occurs when

these gas particles are ionized in an electric field (producing a gas plasma)

and then directing them toward the source or target, where the energy of

these gas particles physically dislodges, or "sputters off," atoms

of the source material.

|

|

Name |

Office |

Extension |

Email |

|

George Lopez |

|

|

glopez@cs.cmu.edu |

Qualified Users List

|

Name |

Office |

Extension |

|

|

|

|

Ê |

Ê |

|

|

|

Ê |

|

|

etc. |

|

|

|

Standard Operating Procedures

Instructions

Applications Notes

Useful Links

Miscellaneous

Sputtering

Calibration Tip

Typically

when sputtering with the Lesker or Indel you'll want to double

check the

sputtering rate and an easy way to do this is with lift-off.>Although lift

off with Kapton Tape is quite common, a simpler, more elegant solution was

taught to me by Matt Moneck:

1. Simply

draw a line on the wafer with a Sharpe marker (or photoresist pen).

2.

Sputter the wafer as intended.

3. Put

the wafer in an acetone ultrasonic bath for 5 minutes to lift off

the

sputtered metal over the drawn line.

If any of the metal hasn't

lifted

off, simply rub it away with an acetone soaked Q-tip.

Since the

Sharpe comes off with acetone, there's no adhesive residue on

the

wafer. Even better, since the Sharpe

line is so low, the "bunny

ears"

effect seen from lifting the Kapton tape doesn't occur.

by

Michael Vladimer

|

|