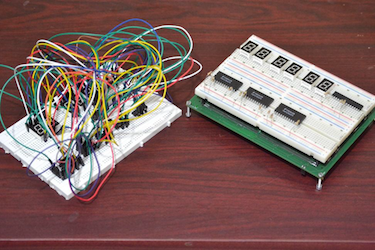

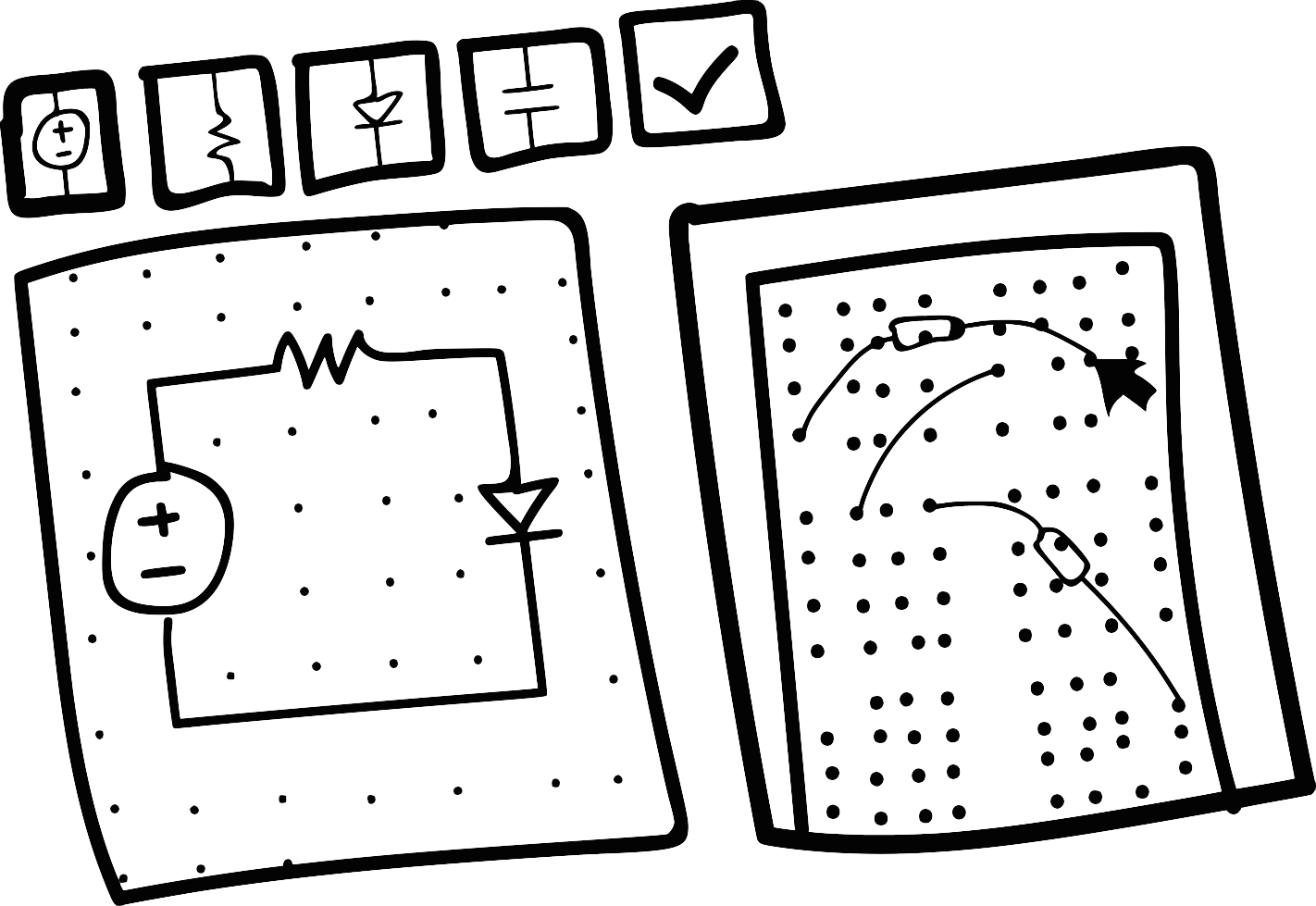

What is (De)Buggy Board?

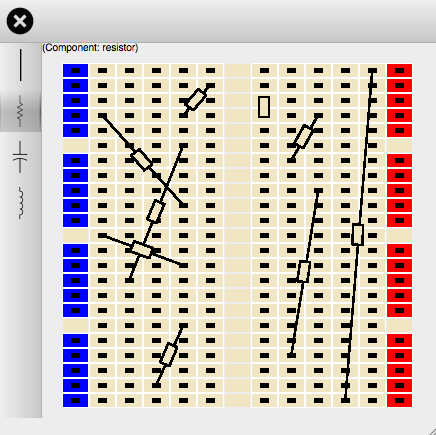

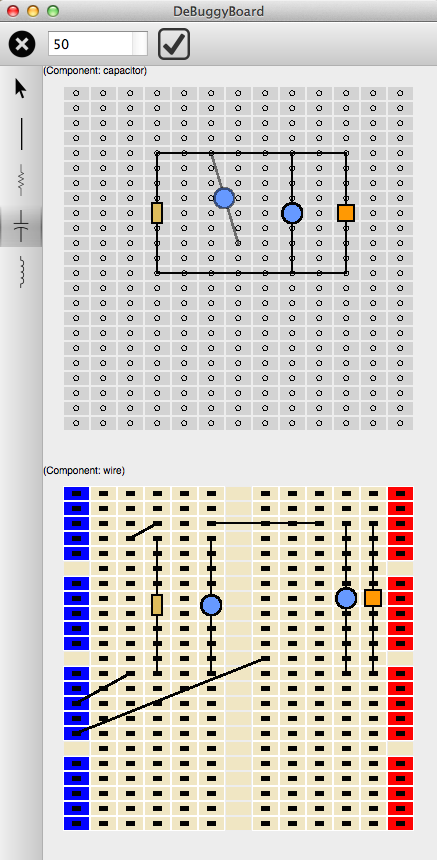

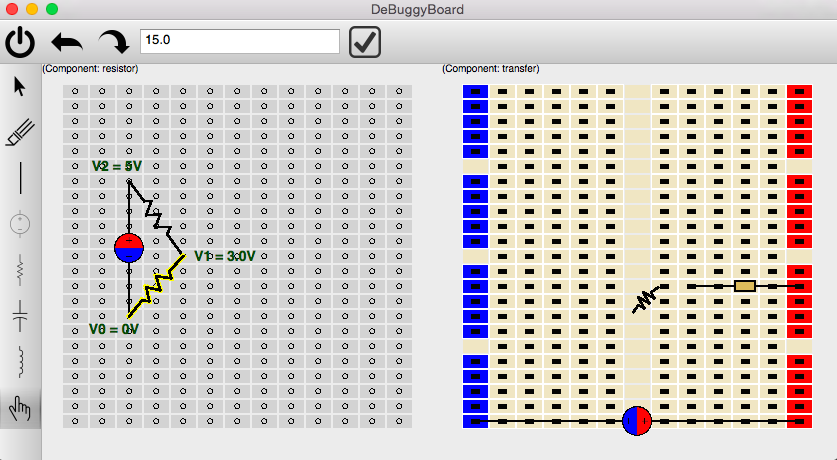

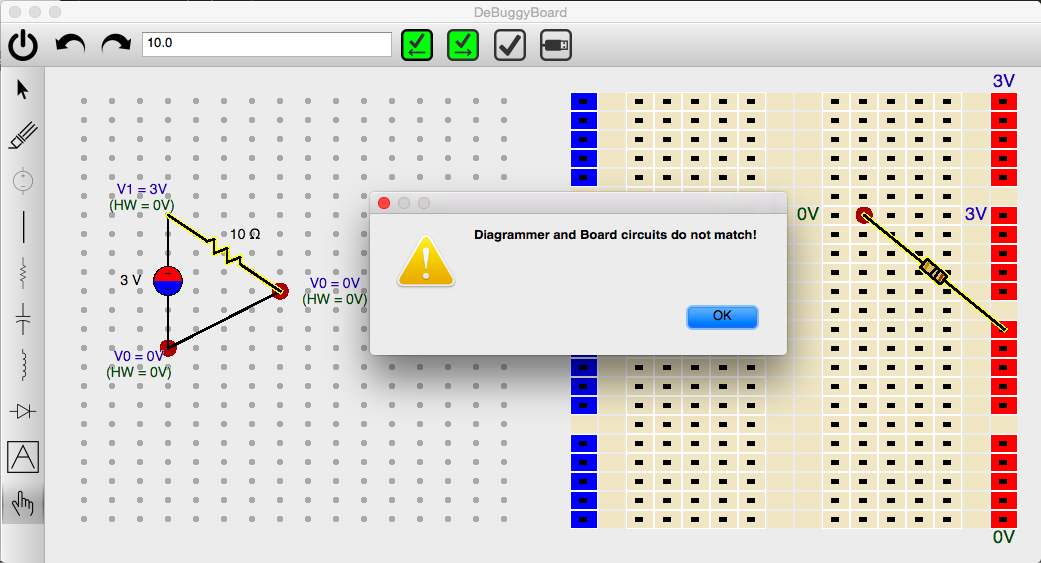

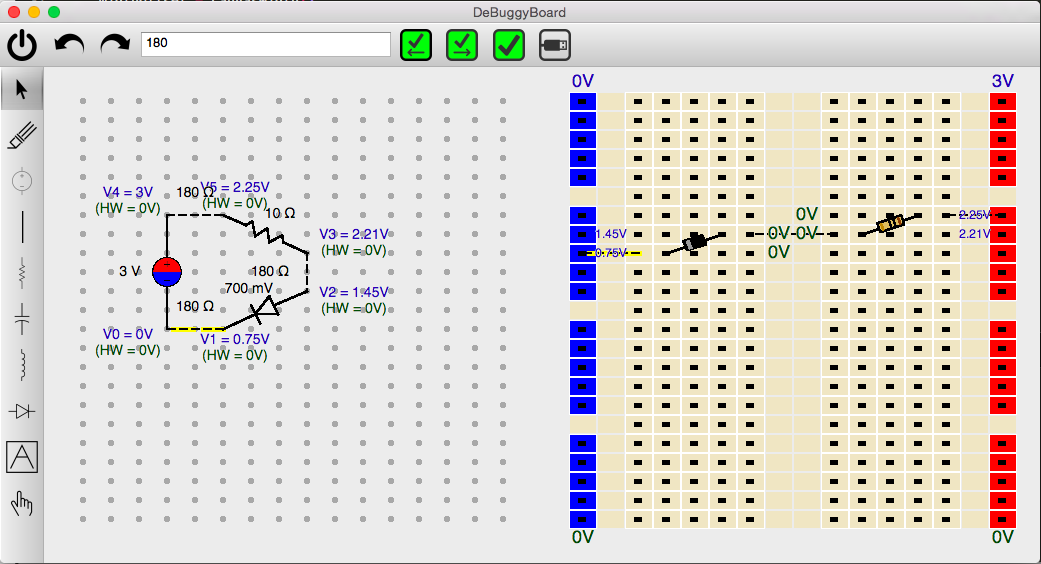

Plan > Connect > Debug

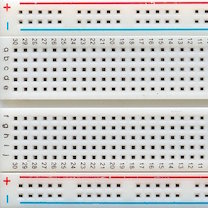

An interactive, educational breadboard to ease circuit-building and debugging.

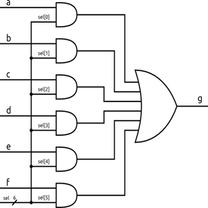

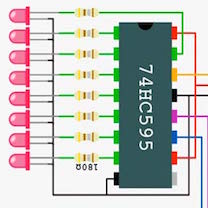

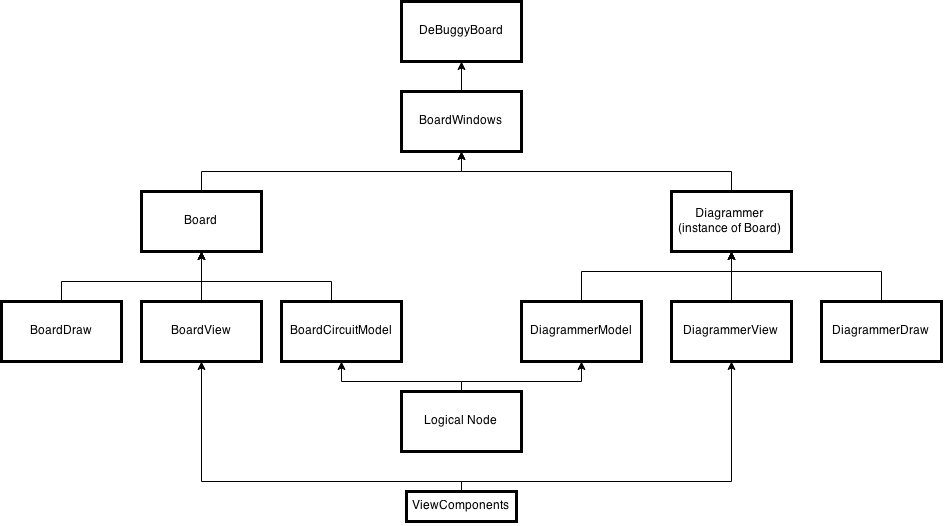

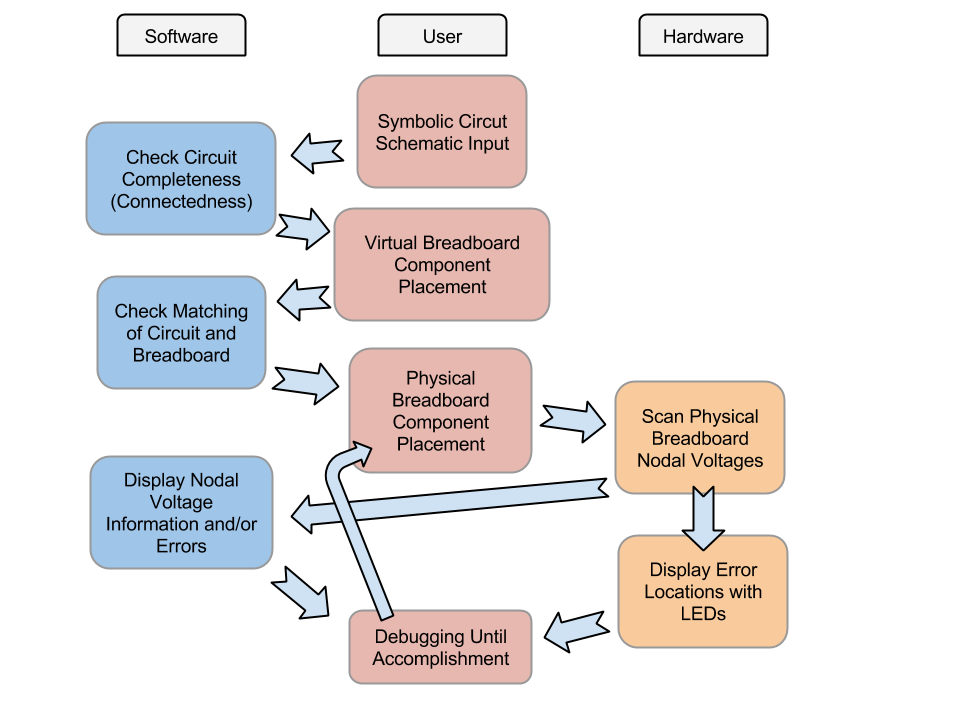

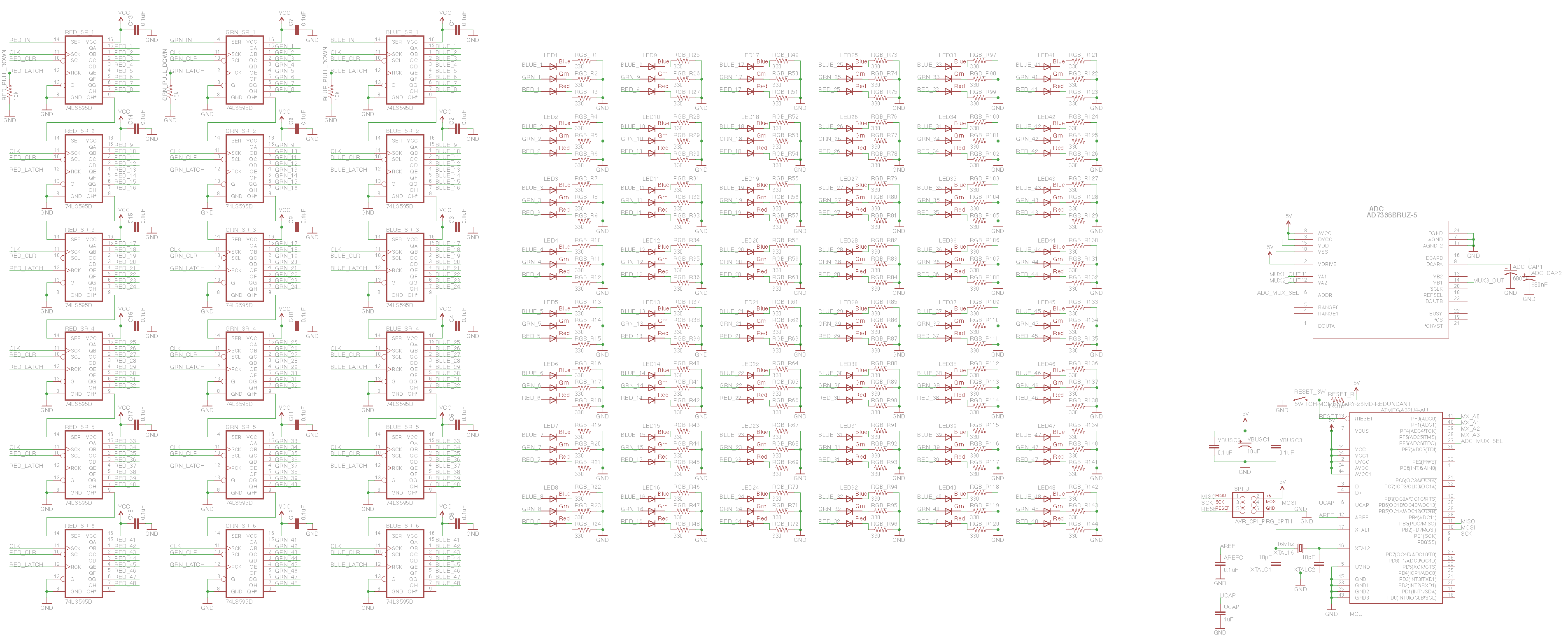

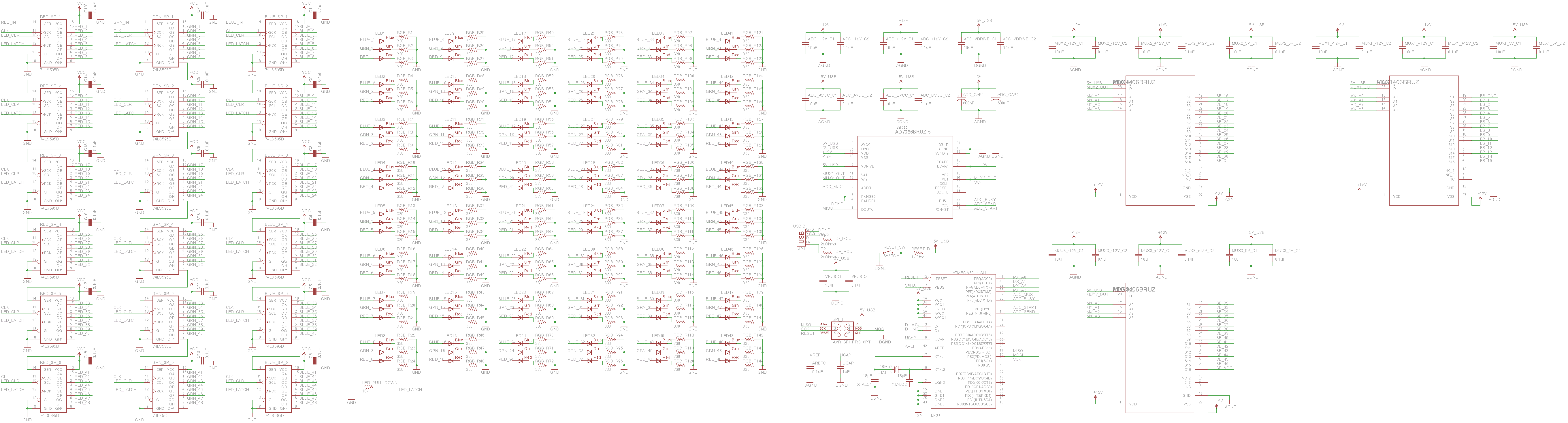

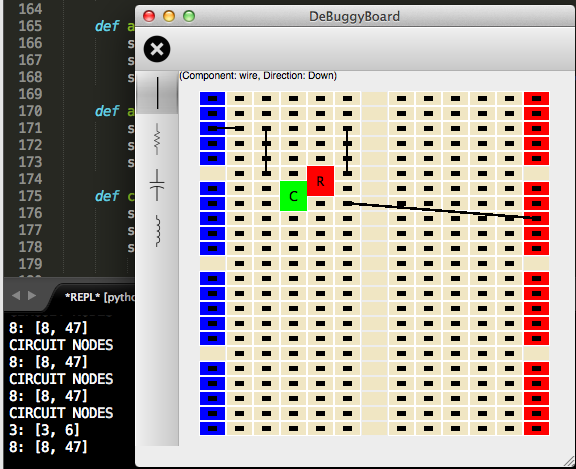

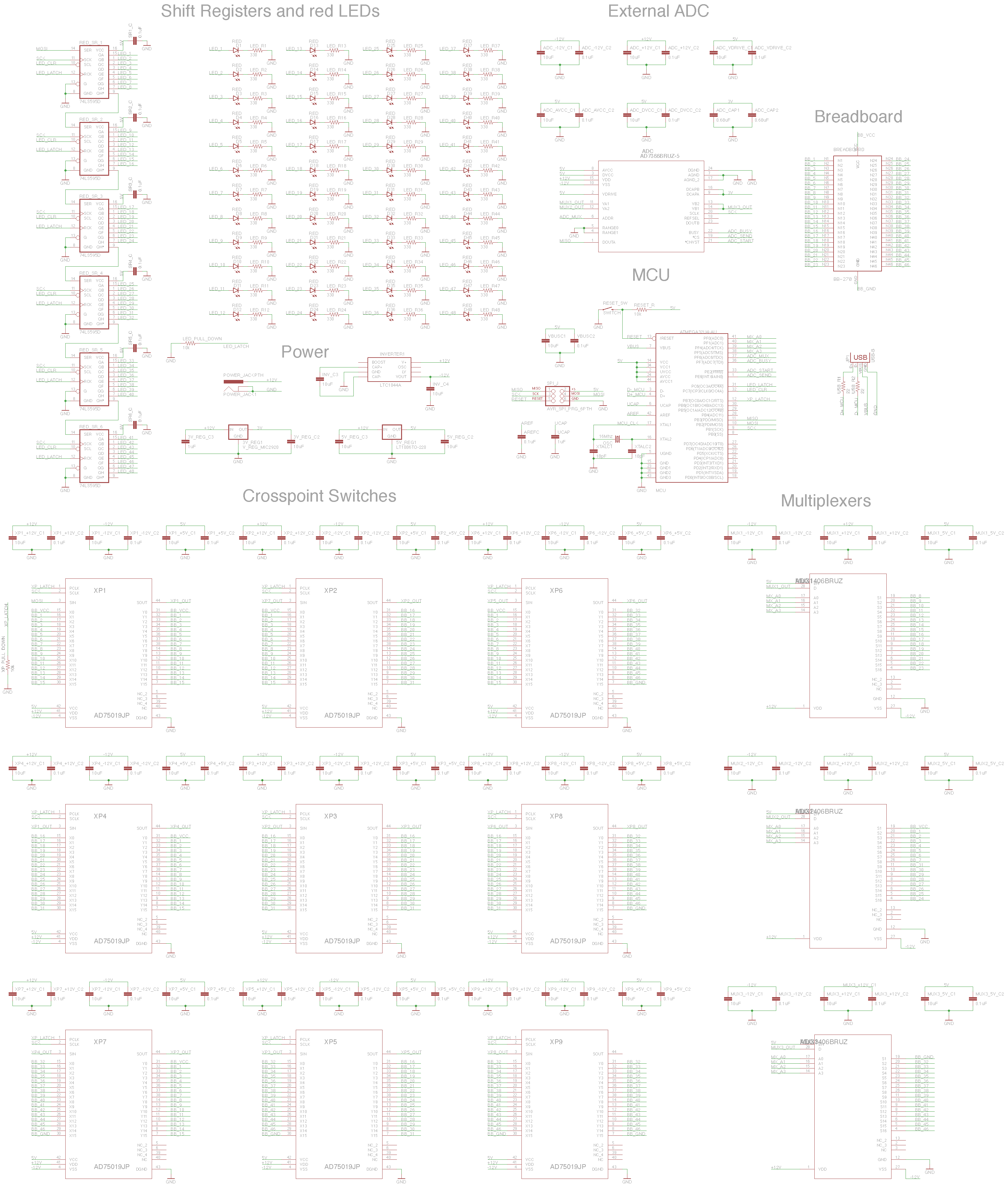

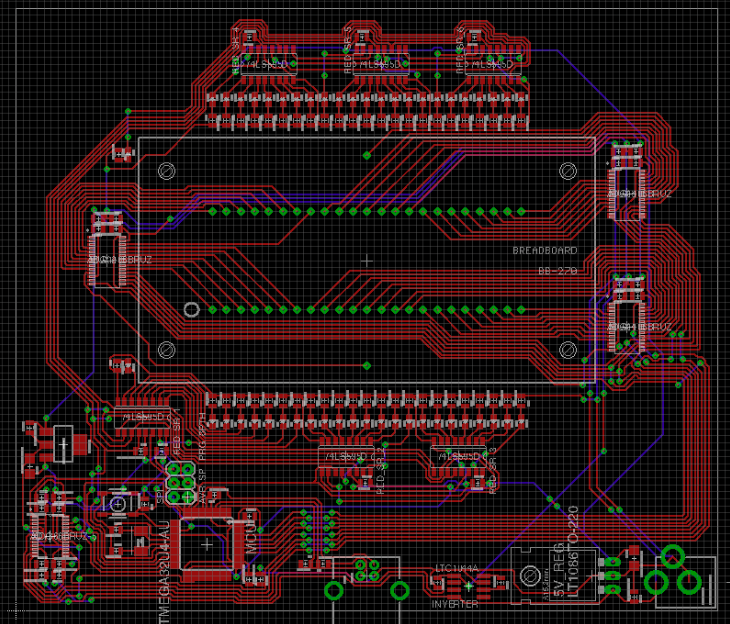

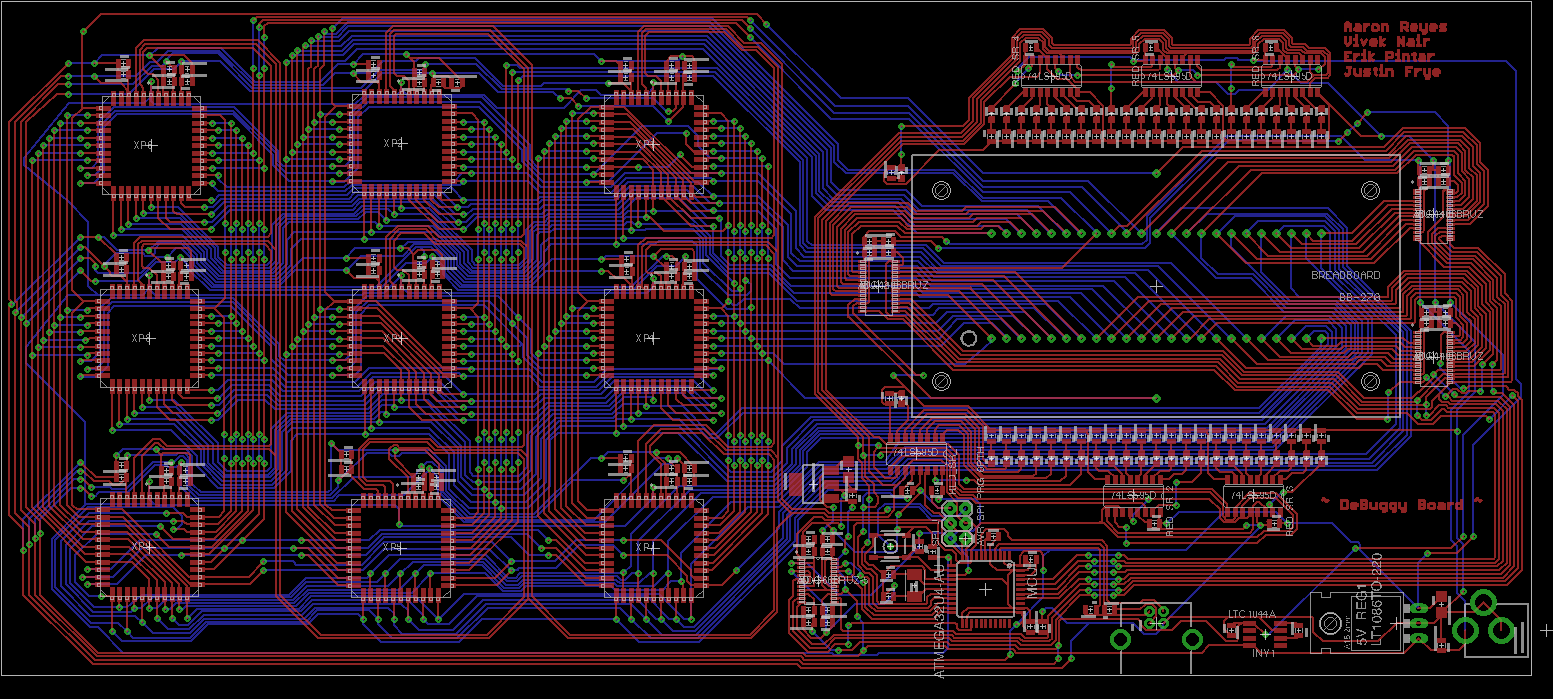

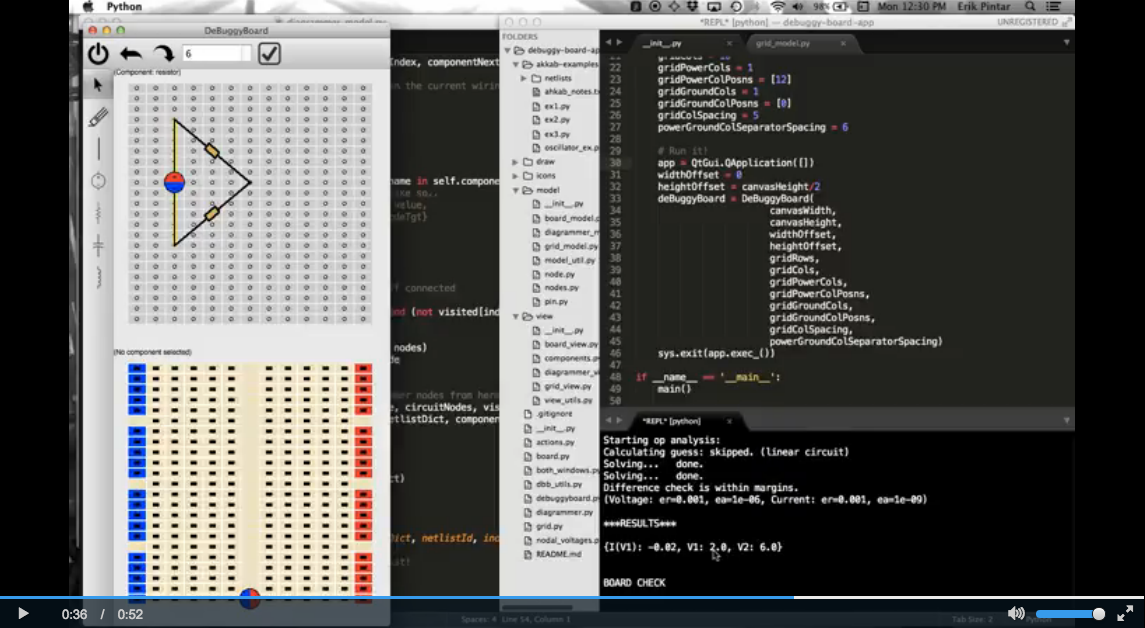

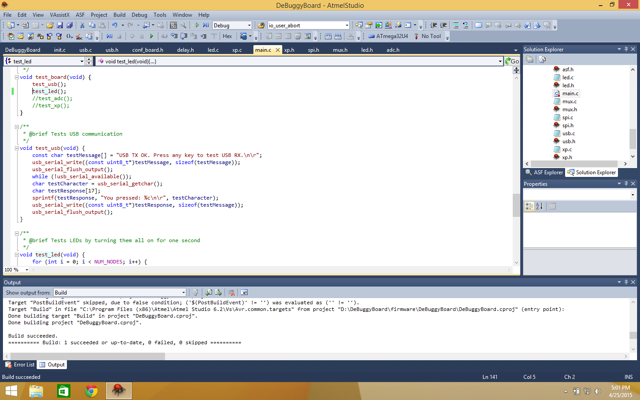

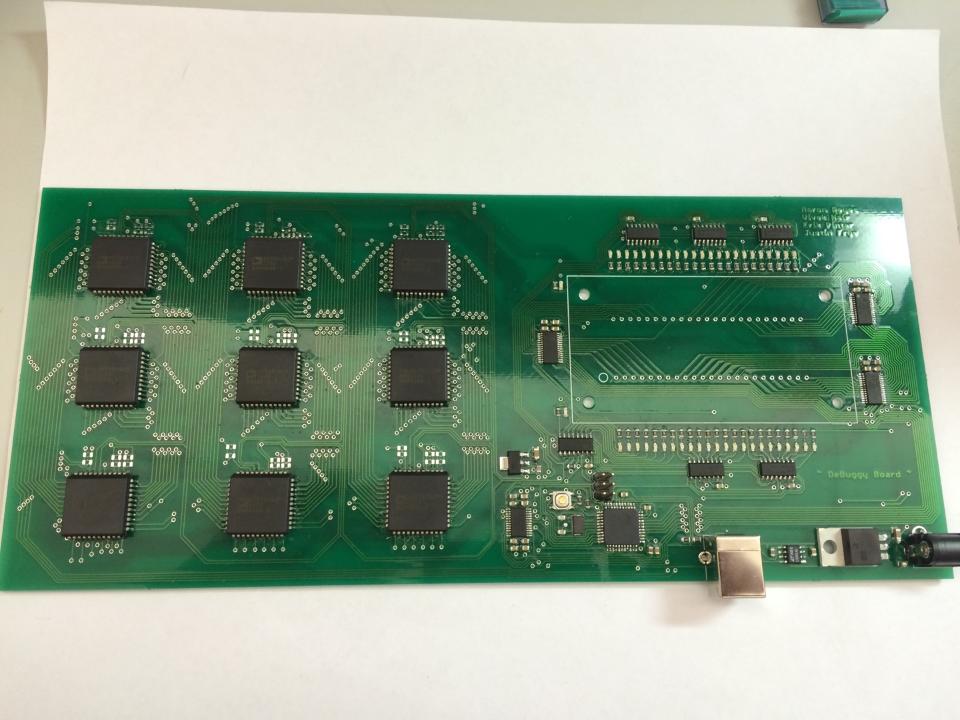

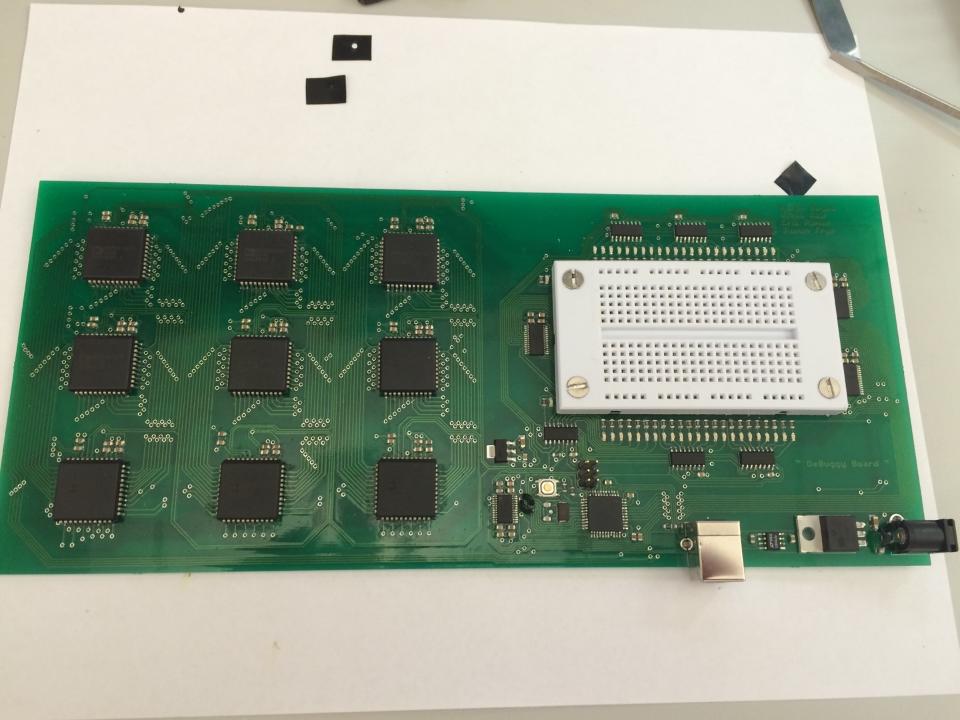

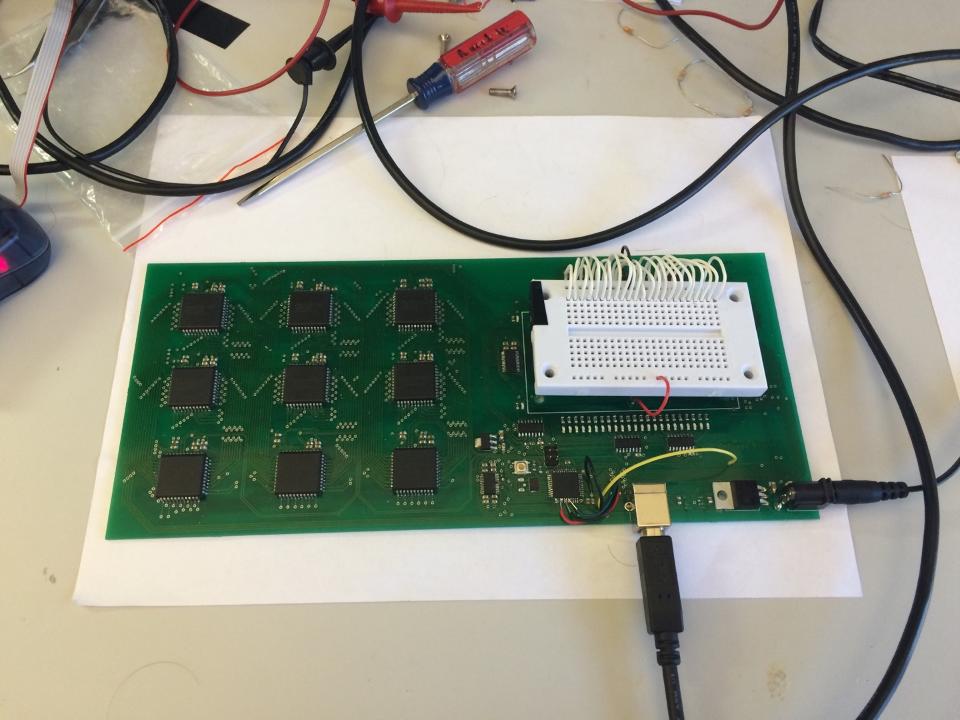

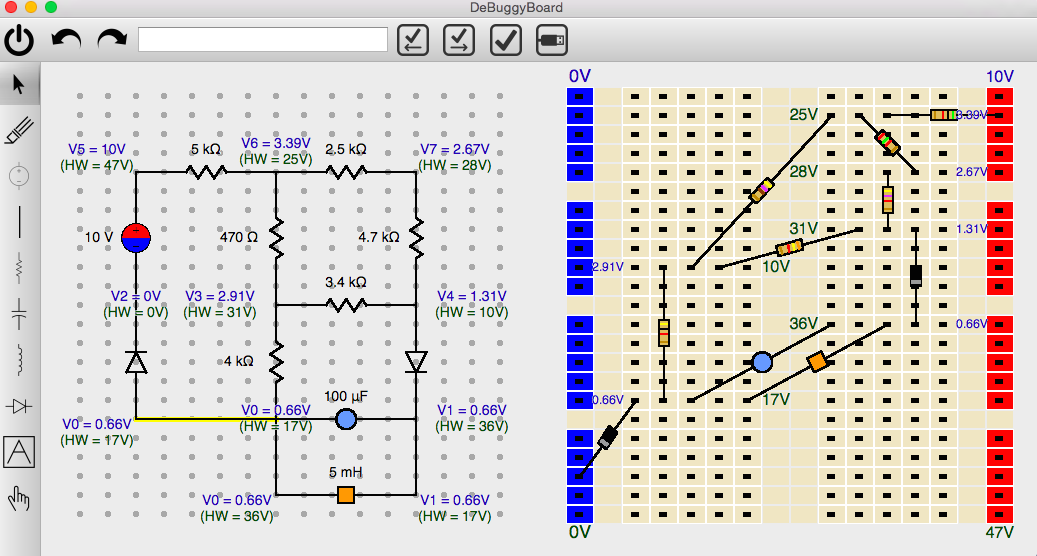

(De)Buggy Board is an interactive, educational breadboard comprising of hardware and software components. Students design the circuit they want to build on a software user interface. Then, as they build it on the breadboard, their circuit design will sync with the software to provide real-time information about their circuit.